SIGHT GLASS

Price 2000 INR/ Piece

SIGHT GLASS Specification

- Measuring Range

- Visual Inspection

- Features

- Corrosion Resistant, Easy Installation, Durable Body, Leak Proof, High Visibility

- Mounting Type

- Flanged / Threaded

- Display Type

- Transparent Glass View

- Port Size

- 1 to 12 Inch (Available in Different Sizes)

- Usage

- For Checking Flow of Liquids in Pipelines

SIGHT GLASS Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 1-2 Week

- Main Export Market(s)

- Asia

About SIGHT GLASS

This Sight Flow Indicator is a reliable and economical product to verify liquid flow for direction and approximate rate. This device is installed in pipelines or pipes for providing visual observation of fluids either liquid, powder or gas. Each device is designed with mica liners for ensuring the high protection of glass against erosion and corrosion. This device finds its application in sugar, fertilizer, paper, chemical, pharmaceutical, food & beverages, paint and other industries. The offered device is resistant to corrosion, quality proven, durable and requires less maintenance. Made up of quality assured materials, we provide this Sight Flow Indicator to the clients in standard sizes and configurations.

-

Operators use sight glasses to see inside enclosed systems, check process stages, and identify changes in fluid consistency or color.

-

They provide a direct visual indication of liquid or gas levels in tanks, boilers, and other vessels, often with a red line or other markings for easy identification.

-

In some applications, sight glasses allow for the visual confirmation of fluid flow or the presence of bubbles, which can indicate issues with refrigerant or liquid supply.

-

A common use in refrigeration systems is a sight glass with a moisture indicator that changes color to signal the presence of water in the refrigerant.

-

Sight glasses are made from strong, transparent glass or polymer substrates, such as borosilicate glass, which are specifically chosen for their ability to resist high temperatures, pressure, and chemical corrosion.

-

They can be installed as discs held in metal frames, tubular sections, or specialized windows, often bolted, clamped, or fused to the equipment.

-

The glass is frequently heat-tempered to enhance its durability and resistance to stress and impact, ensuring safety under severe operational conditions.

Robust and Versatile Construction

Engineered with multiple body material choicesstainless steel, cast iron, brass, or PVCthis sight glass caters to diverse environments. The high-strength borosilicate glass offers thermal and mechanical resilience, making it suitable for demanding industrial settings. Gasket options such as PTFE, rubber, or asbestos ensure a secure, leak-proof seal.

Wide Compatibility and Easy Installation

Available in various port sizes ranging from 1 to 12 inches and connection standards including ANSI, DIN, and JIS, this sight glass is compatible with different pipeline systems. With flanged or threaded mounting and end types, installation is straightforward and adapts to existing infrastructure with minimal adjustments.

Clear and Reliable Process Inspection

Offering clear-view transparency from both sides and available with single or double inspection windows, this sight glass enables real-time monitoring of flow conditions. Choosing among plain, rotor, or flapper indicators enhances the visual clarity for checking the presence or movement of liquids, gases, or chemicals across industrial lines.

FAQs of SIGHT GLASS:

Q: How do I select the right body material for my sight glass application?

A: Choose the body materialstainless steel, cast iron, brass, or PVCbased on the chemical compatibility and mechanical requirements of your process media. Stainless steel offers high corrosion resistance for aggressive chemicals, while PVC is suitable for less demanding environments.Q: What benefits does borosilicate glass provide in this sight glass?

A: Borosilicate glass ensures excellent clarity, high thermal shock resistance, and mechanical strength, making it suitable for high-pressure (up to 10 bar) and high-temperature (up to 180C) industrial applications.Q: When should I use a plain, rotor, or flapper indicator?

A: Select a plain indicator for simple visual inspection. Rotor and flapper indicators are ideal when you need to confirm active flow, as their movement signifies media passing through the pipeline.Q: Where can this sight glass be installed in a processing system?

A: It can be integrated at any point in a pipeline where visual inspection of the media is required, such as before pumps, after filters, or at strategic locations for safety monitoring in industrial settings.Q: What is the process for installing this sight glass?

A: Installation involves attaching the sight glass to your pipeline using the specified flanged or screwed connection, ensuring the gaskets are correctly positioned for a leak-proof seal. Use compatible connection standards (ANSI, DIN, JIS) for a secure fit.Q: How is this sight glass beneficial for process monitoring?

A: It offers high visibility and immediate detection of flow or blockages, helping reduce downtime, improve process safety, and enable timely maintenance, thanks to its clear view and indicator options.Q: What maintenance is required to ensure the sight glass operates effectively?

A: Regularly inspect for glass clarity, gasket integrity, and any signs of leakage. Clean the inspection window as needed and replace gaskets or other parts if wear is observed to maintain leak-proof performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Level Indicator Category

Magnetic level Indicator

Price 9000 INR / Set

Minimum Order Quantity : 1 Set

Product Type : Magnetic level Indicator

Color : White

Usage : Laboratory

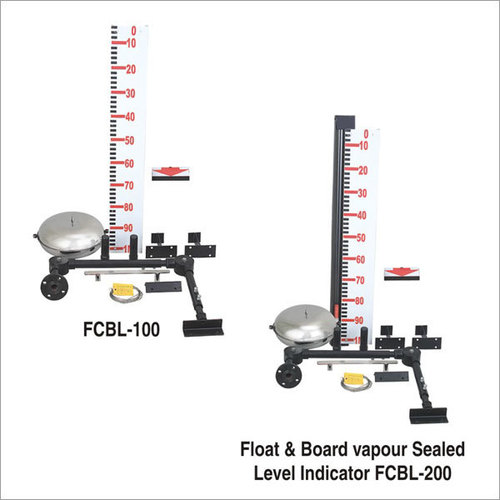

Float and Board Level Indicator

Minimum Order Quantity : 1 Set

Product Type : Float and Board Level Indicator

Color : Grey

Usage : Laboratory

Double Window Sight Flow Indicator

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Double Window Sight Flow Indicator

|

FLOW AND CONTROL SYSTEM PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry